Troubleshooting

Maintenance & Repair service

Please contact us for your equipment repair, maintenance, sales and service needs.

*Provided the machine is used normally and in accordance with the instruction manual and the caution label affixed to the main unit.

Contact us

| Head Office, Tokyo | Head Office, Tokyo

2-4-9 Haginaka, Ohta-ku, Tokyo, 144-0047, Japan TEL: +81-3-3744-1800 FAX: +81-3-3745-2671 |

|---|---|

| Kansai Branch | Kansai Branch

1-3 Tsuto Sumiecho, Nishinomiya City, Hyogo-ken, 633-8234, Japan TEL: +81-798-36-5480 FAX: +81-798-36-4917 |

| Komatsu Oil Filters Malaysia Sdn. Bhd. |

Komatsu Oil Filters Malaysia Sdn. Bhd.

Komatsu Oil Filters Malaysia Sdn. Bhd. NO.3 Jalan Mutiara Emas 5/2, Taman Mount Austin, 81100 Johor Bahru, Malaysia TEL +60-7-364-5530 FAX +60-7-364-5520 |

Troubleshooting

| Anomaly | Main cause | Countermeasure |

|---|---|---|

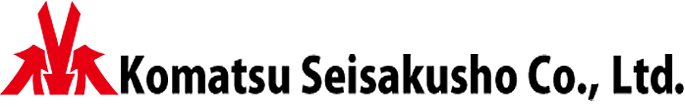

| Motor doesn’t work even when the switch is turned on | Power cord is not plugged in | Plug in the power cord |

| Power cord is damaged | Replace the power cord | |

| Power cord is disconnected from the switch | Reattach the power cord to the switch | |

| Switch is damaged | Replace the switch | |

|

||

| Anomaly | Main cause | Countermeasure |

|---|---|---|

| Switch is turned on, but the machine cuts out/turns off *If you try to force the switch to turn on and attempt to turn the motor, the motor may emit smoke and break down |

Check if the hose is clogged Remove the hose and blow into it or run water through it |

If the hose is clogged, replace the hose |

| Expansion inside the pump | Wait a couple of minutes and then turn on the switch | |

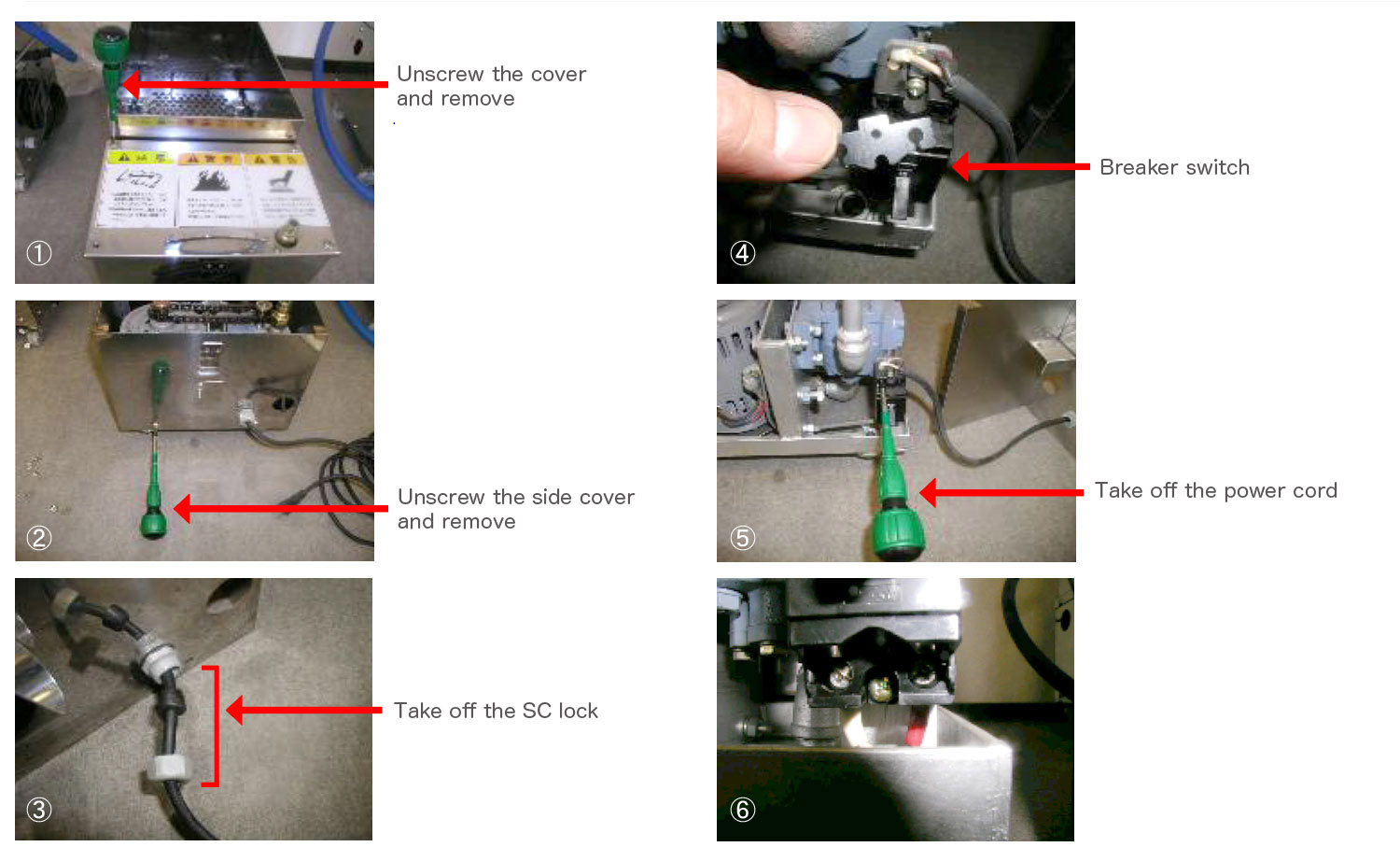

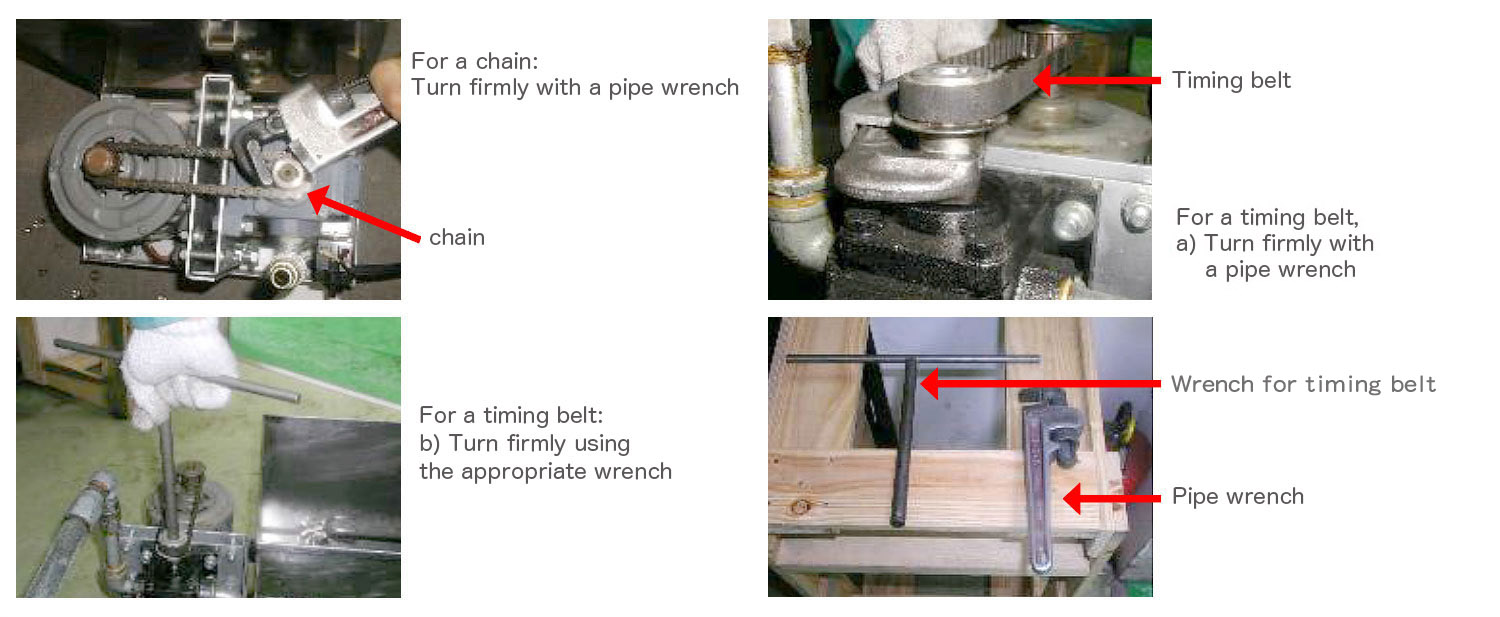

| Check that sediment is not inside the hose (pump lockup). If there is, the chain or timing belt cannot be turned by hand |

If the pump is locked, release the pump lock with the pump release stick or a pipe wrench If you cannot unlock it using a pipe wrench, please overhaul or replace the pump |

|

|

||

| Switch is damaged | Replace the switch | |

| Check if the electronic parts have come into contact with water and caused a short circuit | If there has been a short circuit, please dry out the electronic parts. If the problem isn’t solved after drying, please change the electronic parts | |

| Check if the power cable’s coating has peeled off to cause a short circuit | Replace the power cord | |

| Anomaly | Main cause | Countermeasure |

|---|---|---|

| Pump sound is too loud | Filter(Filcopad) is clogged | Replace the filter (Filcopad) |

| Pump bearing is damaged | Replace the pump bearing | |

| Caster won’t move | Caster is damaged | Replace the caster |

|

||

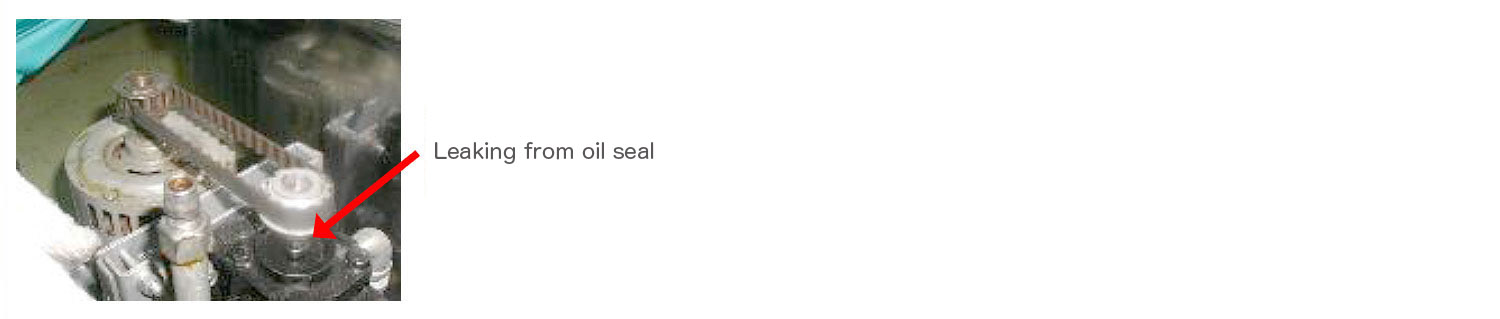

| Oil is leaking ●Leaking from pump |

Pump oil seal is damaged | Replace the pump oil seal |

|

||

| ●Leaking from hose | Hose is damaged | Replace the hose |

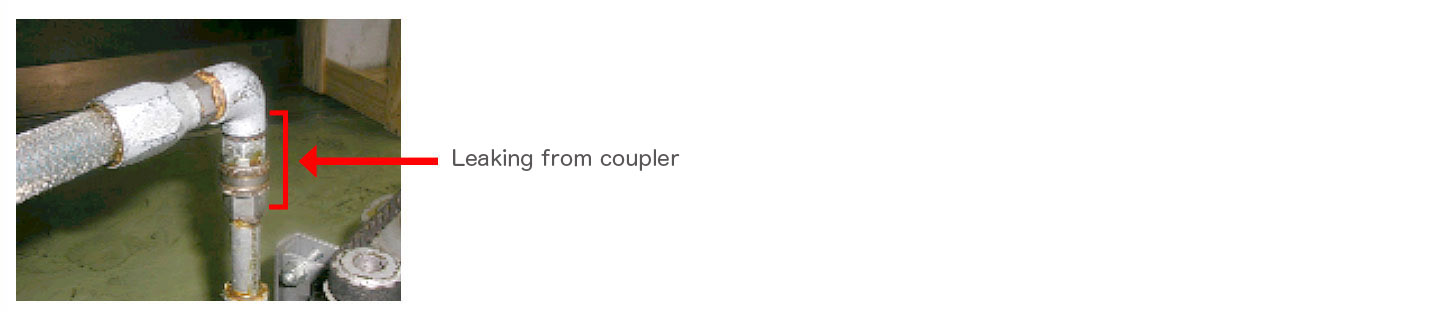

| ●Leaking from coupler | Coupler is damaged | Replace the Coupler |

| O-ring inside of coupler is damaged | Replace the O-ring | |

|

||

| ●Leaking from flexible tube | Flexible tube is damaged | Replace the flexible tube |

| Anomaly | Main cause | Countermeasure |

|---|---|---|

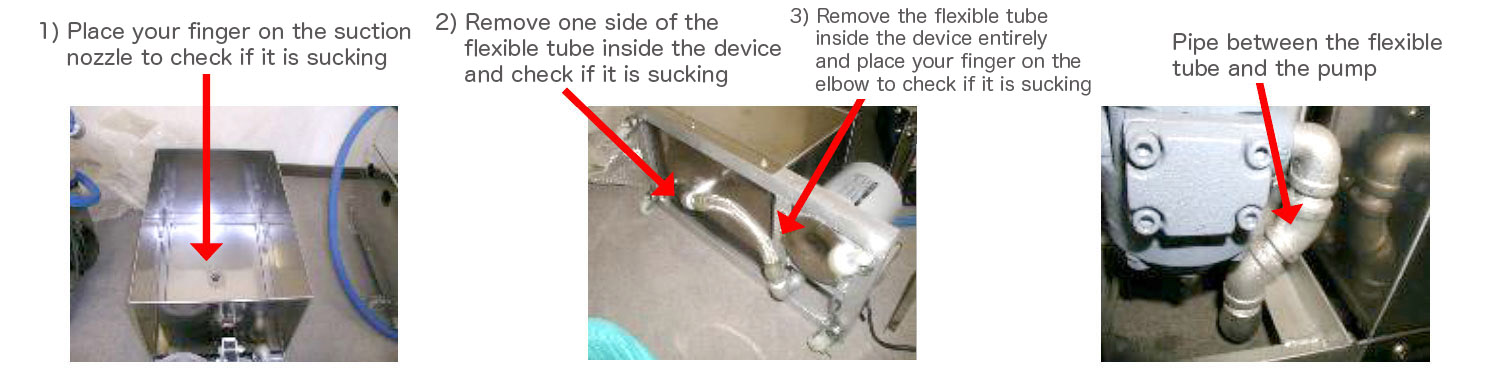

| Does not filter even though the motor is running *In some cases smoke may be seen coming out from the end of the hose, but this is due to heat cause by friction within the pump |

Filter (Filcopad) is clogged | Replace the filter (Filcopad) |

| Oil is not hot enough | Heat up the oil to at least 120℃ | |

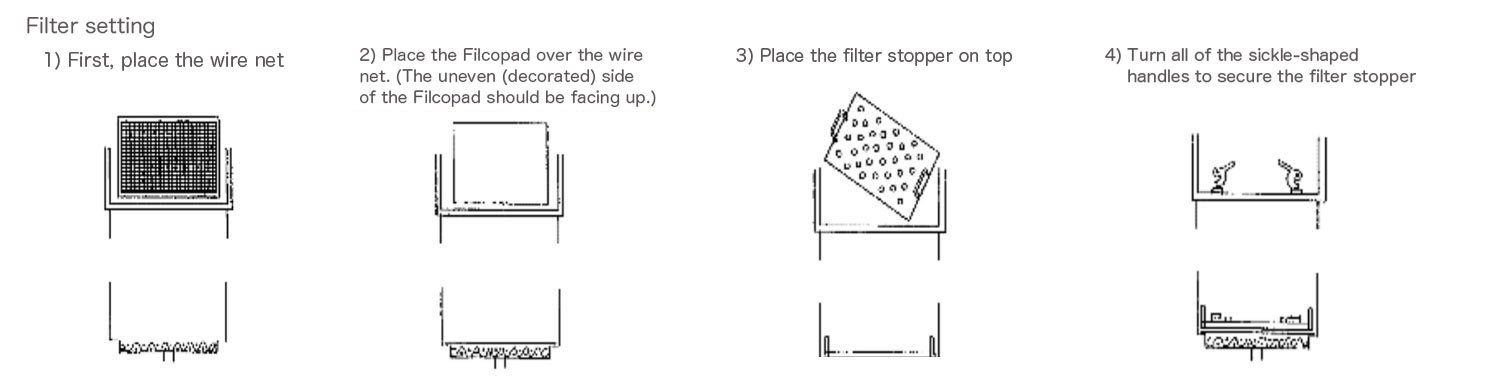

| Filter has been set incorrectly | Set the filter properly | |

|

||

| Flexible tube is cracked and air is being sucked in | Replace the flexible tube | |

| Pump oil seal is damaged | Replace the pump oil seal | |

| Scum or impurities are clogging the pipe between the pump and the flexible tube | Remove the impurities | |

|

||

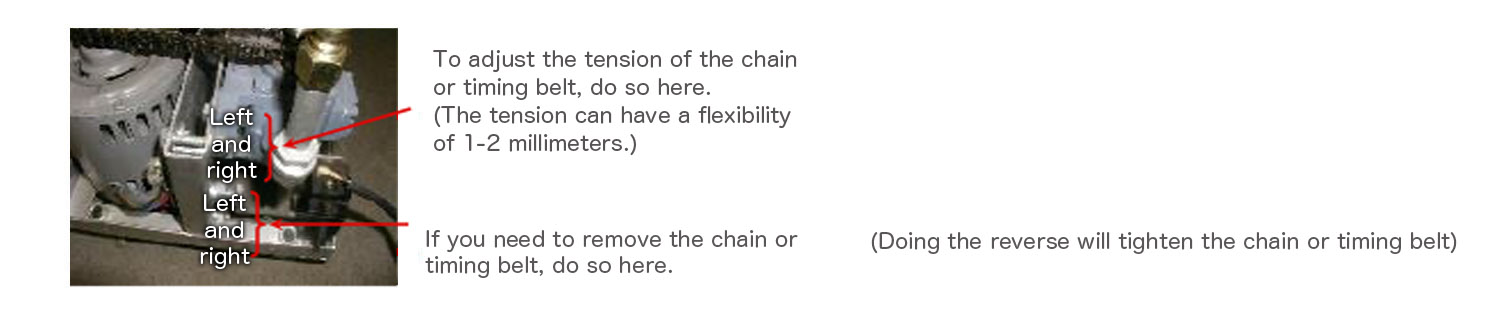

| Check that the chain or timing belt are connected correctly | If has come off, put it back on correctly. If it has stretched, replace with a new part | |

|

||