Necessity of Oil Filter Machines

Today we are presented with more opportunities to eat fried foods than ever before. The large variety of fried food items available from many different food companies has increased the number of fryers and fryer operation times. Taking the food-service industry as an example, the cost of cooking oil is estimated to account for 1.2%-1.6% of sales and 15%-25% of profits. Some of the greatest challenges associated with cooking oil use are oil deterioration and handling issues, including cleaning of oil fryers. Many food plants today have 24-hour operations and the cleaning of fryers is a major undesirable and costly task. While fryer cleaning and oil filtering is not a favored chore among daily tasks, efficient and effective oil maintenance using Komatsu machines and products will improve the quality of oil in use, delivering fine food products and reducing oil replacement and labor costs for business profitability.

Why is an oil filter machine necessary?

Komatsu Oil Filter Machines

The final solution for your oil filtering needs

Komatsu’s oil filter systems can resolve issues once and for all. For example, our compact type Y-Series oil filter machine can readily fit in place of the container for oil under a hand fryer, and oil can be conveniently drained directly into the machine body. This practical design delivers efficient filtering in minimal time, while simultaneously enabling the user to clean the fryer with filtered oil. Not only does it extend the life of the oil, it also reduces the risk of burns and other incidents, making it a product that is easy to use for work.

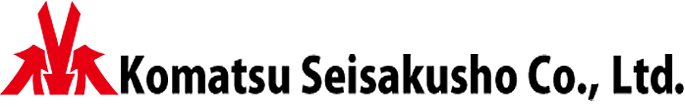

Also, the KF model continuous circulation system, which is a large oil filter machine, removes impurities from the oil during the process of frying, improving the quality of the product without negatively affecting the oil and also extending the oil life. Fried foods are left with a beautiful color and sheen. Machine operation is easy, and fryers can also be easily cleaned.

Easy Operation

- 1)

- Plug the power cord into the electric outlet

- 2)

- Drain the oil from the fryer into the filter tank

- 3)

- Switch the filter machine on

- 4)

- Clean the fryer with filtered oil

- 5)

- Clean and remove the scum in the fryer by directing the oil from the outlet pipe and allowing the oil to then drain into the filter tank below

- 6)

- Return the filtered oil into the fryer

Oil Filter Machine Selection Criteria

Our machines deliver all of the following benefits

- Sizes, capabilities, and features that are optimal for the worksite

- Excellent filter performance, and cost-effective running costs

- Durable design, and failures are rare

- Easy operation, and reduction of daily tasks

- In addition to installing and setting up the filter, we also provide advice on daily operations

- A reliable support structure that provides reassurance through continuous maintenance after installation

- We conduct research and development every day and can rapidly respond to next-generation needs

- We have a proven track record all across Japan and also overseas, removing clients’ uncertainties about future development

- We provide advice that is optimal for the worksite and can support special orders

Our oil filter system specialists will suggest the most suitable oil filter machine for your facility, explaining in detail the capacity and operation method. We stand prepared to provide the most suitable oil filter system that combines greater efficiency and user-friendliness at a reasonable price. If you have any further questions, please do not hesitate to contact us!