Custom Orders

Order-made modifications for customer needs

■Komatsu offers a wide selection of standard products for nearly

every field.

However, we recognize that unique customer needs and facilities may at times merit limited customization of equipment to provide a tailored solution. Our unique depth of experience in developing, designing, and manufacturing a wide selection of oil filtration products in-house enables Komatsu to expertly propose the most suitable system for your situation. (E.g., changing the size, adding a handrail, adding a drain, installing a water-cooling system in the oil tank, installing an oil blending system with automatic flow measurement)

Our oil filter system specialists will suggest the most suitable system modifications for your facility, explaining in detail the capacity and operation method. We stand prepared to provide the most suitable oil filter system that combines greater efficiency and user-friendliness at a reasonable price. We are committed to delivering a prompt response to customer requests for equipment modifications.

Customization examples /

Restaurants and Fast Food

1. Adding a handrail to the oil filter machine

Customer

request

This client used multiple fryers and employees had to bend over to move the oil filter machine. As the filter machine is heavy, the client was worried about the strain.

Komatsu’s Solution

We added a handrail to the oil filter machine. Now, employees can move the oil filter machine around like a push cart, reducing the stress on the lower back. The client was very pleased with this solution.

2. Preventing solid oil from solidifying inside the filter

Customer

request

A client using solid oil had a problem with the oil solidifying inside the oil filter machine.

Komatsu’s Solution

We retrofitted the filter machine with an oil drain to allow all the oil inside the filter machine to drain out. Now that the oil can be perfectly drained out, there is no longer an issue of remaining oil solidifying inside the filter machine.

Oil drain

3. Stowing the oil filter machine under the fryer

Customer

request

This client wanted to fit the filter machine neatly under the fryer to save space in their small kitchen.

Komatsu’s Solution

By separating the pump and oil tank of the filter machine, we were able to fit the filter machine neatly under the fryer.

Oil tank and pump set

4. Stowing the oil tank under the fryer

Customer

request

This client wanted to stow the oil tank underneath their fryer to save space.

Komatsu’s Solution

We incorporated a filter machine with a detachable oil tank, with only the oil tank installed just below the fryer. Since the filter machine can be stored separately when not in use, the client was able to make effective use of a small space.

Oil tank

Filter machine (portable)

Customization examples / Food Factories

1. Installing the filter machine and oil tank away from the fryer

Customer

request

This client wanted to install the filter machine and oil tank away from the fryer.

Komatsu’s Solution

Our vacuum filtration system can be installed 30 meters or more away from the fryers they serve. It can also be controlled from far away with the press of a button to easily suck out the oil inside the fryer and filter it.

2. Preventing oil from solidifying in the pipe and oil tank

Customer

request

This client was using solid oil, and was having trouble supplying oil to the fryer because the oil cooled and solidified inside the tank and pipe, affecting production.

Komatsu’s Solution

We attached a heater to the oil tank. Our heaters use precise temperature control to prevent oil oxidation. We also surrounded the pipe with heating elements, insulation and metal jacketing. This prevented the oil in the tank and pipe from solidifying even during the cold winter season, allowing production to continue smoothly.

3.Decreasing the temperature of the oil in the tank as quickly as possible

Customer

request

A client making rice crackers fries them in oil at temperatures of more than 200 degrees Celsius. After production, oil was returned to the oil tank with a filter machine, but it took a long time to cool down, increasing the acid value of the oil in the tank.

Komatsu’s Solution

We retrofitted a water cooling system to the oil tank (pipes inside the oil tank with water flowing through them). The oil temperature inside the tank decreased immediately, successfully preventing oxidation.

Filter machine’s tank

Water-cooling pipe in the tank

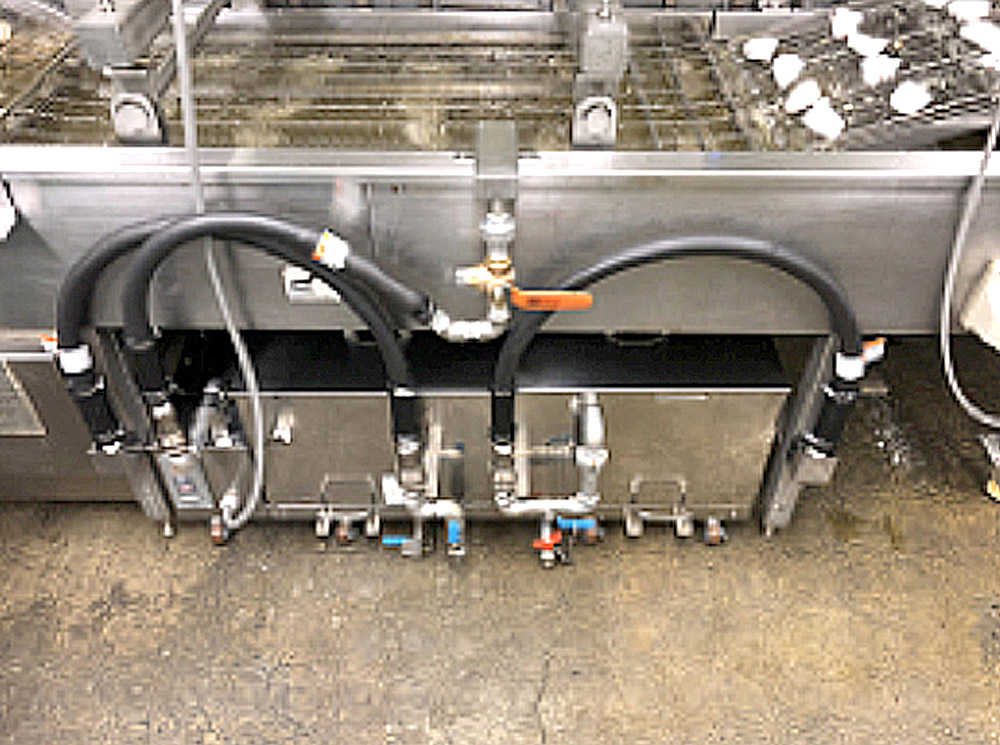

4.Automating the measurement and blending of oil

Customer

request

This client blends 2 types of oil for frying. The client measured and blended the oil manually, but it was very labor-intensive, so they asked us to automate this process.

Komatsu’s Solution

We added a flow meter to the existing oil tank and a mixer to the blending tank. After automatically measuring the amount of oil, the oil is sent to the blending tank to be automatically blended. Automating these processes increased work efficiency and improved the accuracy of the oil ratio in the blend.